The COVID-19 pandemic has thrust protective gloves and masks, among other personal protective equipment (PPE), into the spotlight like never before, leading to a surge in the emergence of PPE manufacturers, creating a market where products vary widely in quality and consumers often find it overwhelming to distinguish between good and inferior items. In the realm of protective glove products, there exist internationally recognized performance standards that guide the industry, such as EN388, EN511, EN407, EN374, and EN ISO 21420. To claim that a glove offers protection against mechanical risks, it must undergo assessment according to the EN388 standard, which evaluates the abrasion resistance, tear resistance, cut resistance, puncture resistance, and impact protection properties of the glove. Under this standard, laboratory tests assign the glove different performance levels based on its results. Consumers can not only verify whether a glove possesses mechanical protective capabilities by checking if it carries EN388 certification but also make informed decisions by selecting work gloves that match their specific protection needs based on the performance grade indicated by the standard.

This topic will provide professional science popularization in a detailed graphic way, explain the meaning of the performance level of EN388 and the test methods of various performance, after reading the protective gloves can also quickly get to the important knowledge points of EN388.

The meaning of EN388

EN388 refers to one of the European Standards for industrial protective gloves, which was approved by the European Committee for Standardization (CEN) on July 2nd, 2003, in the form of version EN388:2003. Subsequently, EN388:2016 was published in November 2016, superseding EN388:2003, and later revised with an additional amendment in 2018, resulting in the updated version EN388:2016+A1:2018.

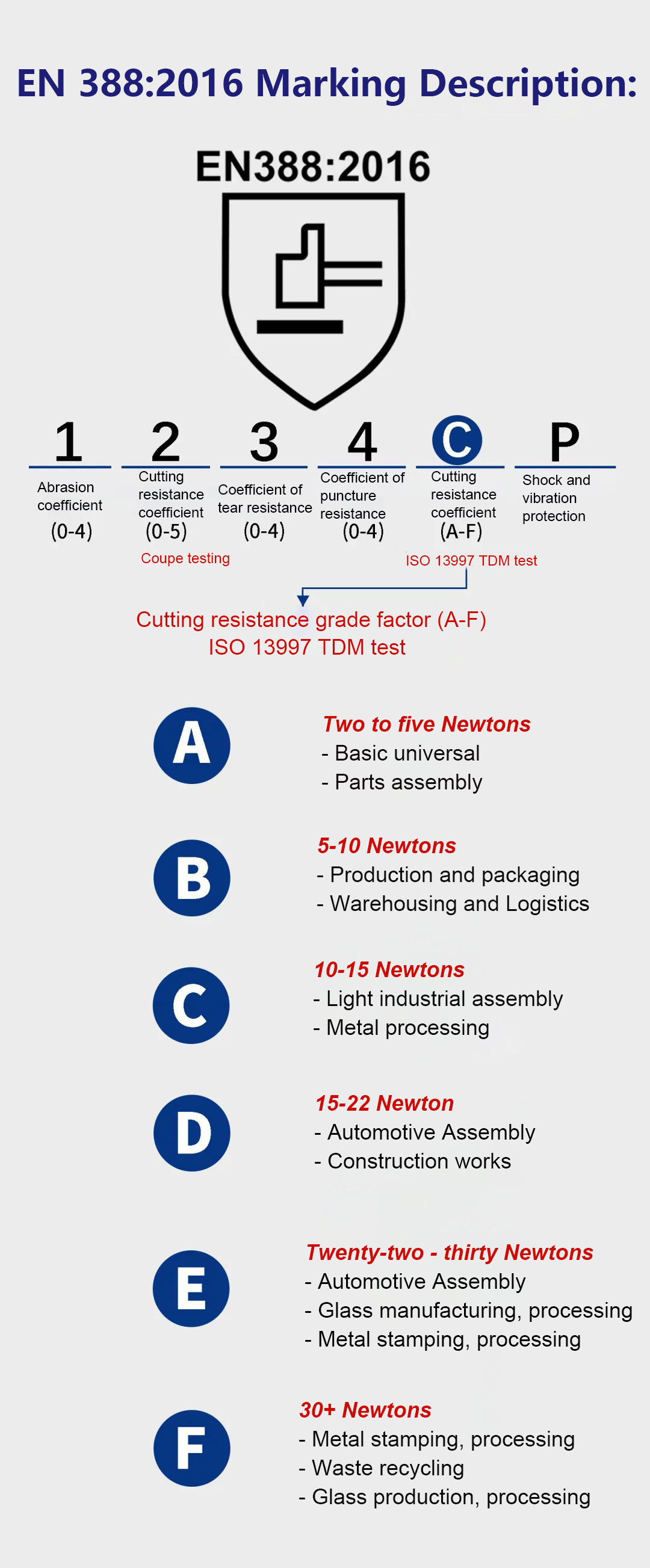

EN388 grade coefficient and test method

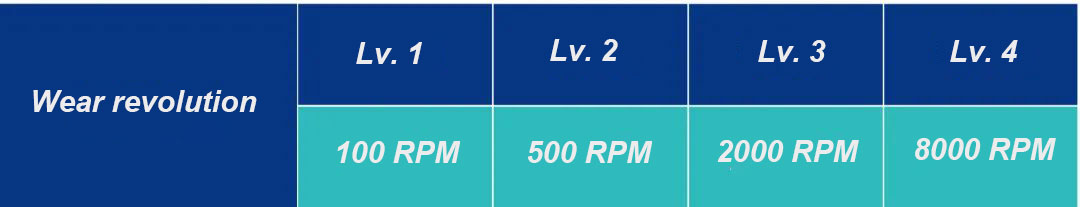

1, Wear coefficient

Test instructions:

Take the glove palm material, wear it with sandpaper under a fixed pressure, calculate the number of revolutions until a hole appears on the wear material, wear level from 1 to 4 numbers indicate that the higher the number of revolutions, the better the wear resistance.

Test equipment - Martindale Wear Tester:

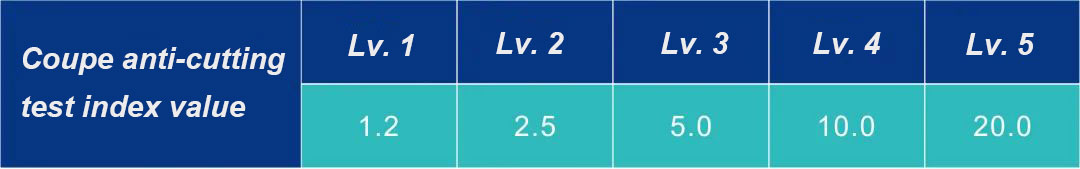

2, Anti-cutting coefficient

Test instructions:

A rotating circular blade is moved horizontally back and forth across the glove sample, recording the number of blade turns as the blade penetrates the sample. The same blade is used to test the number of cutting circles of the standard canvas before and after the sample test, and the wear degree of the blade during the sample and the canvas test is compared to determine the cutting resistance of the sample. The cutting resistance is divided into 1-5 grades, which are represented by 1-5 numbers.

Test equipment -SATRA Anti-cutting Tester:

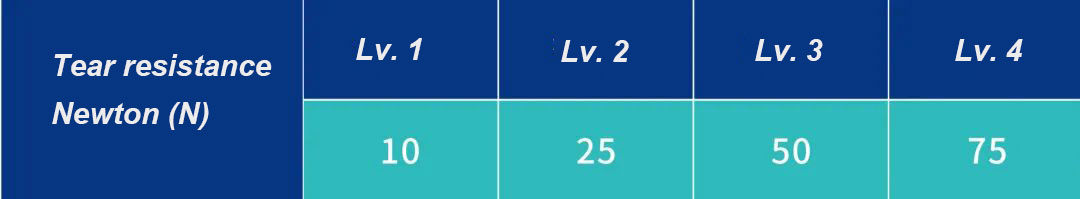

3. Tear resistance coefficient

Test instructions:

The material of the glove palm is torn by the pulling device, and the level of tear resistance of the product is determined by calculating the force required for tearing, which is represented by a number between 1 and 4. The higher the force value, the better the tear resistance. (Considering the characteristics of the textile material, the warp and weft, tear test includes both transverse and longitudinal tests.)

Test equipment -SATRA Tensile Tester:

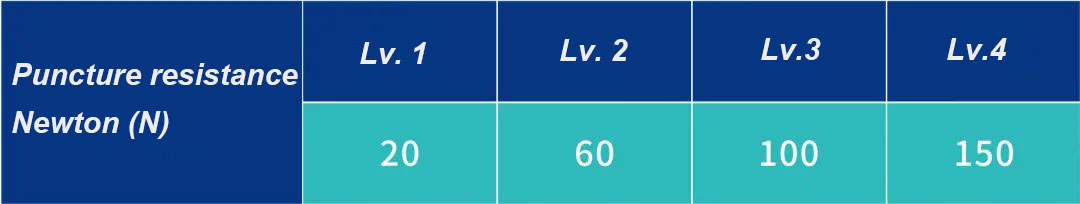

4. Puncture resistance coefficient

Test instructions:

Pierce the glove palm material with a standard needle, and determine the degree of puncture resistance of the product by calculating the force used to Pierce, as indicated by a number between 1 and 4. The higher the force value, the better the puncture resistance.

Test equipment:

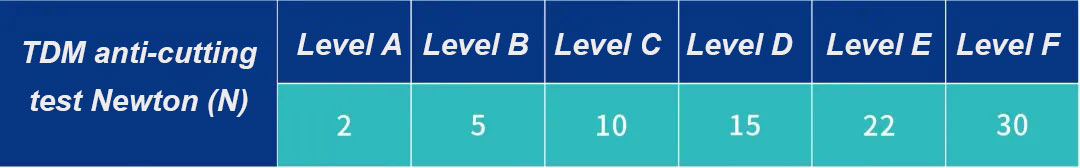

5, Cutting resistancecoefficient

Test instructions:

TDM cutting test is to use a blade to cut the glove palm material at a constant speed, test the walking length of the blade when cutting through the sample under different loads, and use a precise mathematical formula to calculate (slope) to find out how much force is required to make the blade cut through the sample when walking 20mm.

This test is A new addition to EN388:2016, and the result grade is indicated by A-F, with F being the highest grade. Compared to EN 388:2003 coupe tests, TDM tests can provide more accurate indicators of working anti-cutting performance.

Instructions:

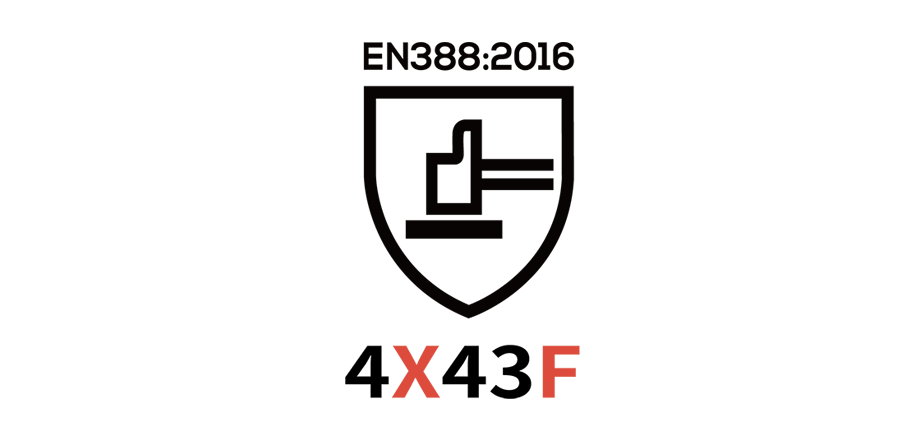

If, during the Coupe test, the material blunts the blade, the cutting test of EN ISO 13997 (TDM test) is performed, the result of the TDM cutting test will be the fifth character mark displayed on the glove, and the Coupe test value will be marked with an "X", as shown below:

Test equipment -TDM anti-cutting tester:

6. Impact protection

The sixth character represents shock protection, which is an optional test. If the gloves have been tested for impact protection, this information is given by the letter P as the sixth and final symbol. Without P, gloves do not have impact protection.

An understanding of EN 388:2016 can help workers determine which gloves have the appropriate level of protection in the work environment to prevent the corresponding mechanical risks. For example, construction workers may often encounter wear hazards and need to choose gloves with higher wear resistance, while metal processing workers need to prevent cutting tool cutting injuries or scratches on the sharp edges of the metal, which requires the selection of gloves with higher cutting resistance levels.

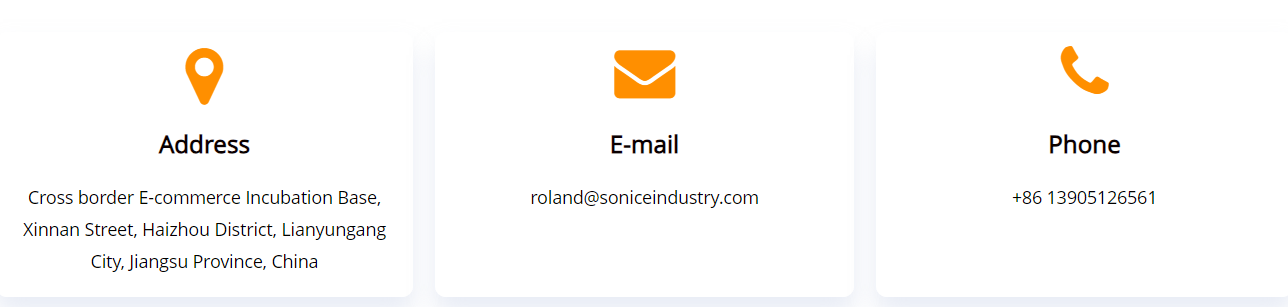

SONICE is a quality manufacture of Safety gloves, including Mechanic gloves, Impact gloves, Cut resistant gloves, Tactical gloves and Garden gloves. Due to increasing of customer demand, we have expanded our products range to include Safety clothing, Safety helmets, Safety shoes. Welcome to contact us.

Post time: Apr-11-2024